Klassikaliselt läikiva pinnaga, soliidne, kindel ja stabiilne materjal.

Kivimass

Kogub ja hoiab soojust

Kõva ja vastupidav nagu kivi

Raske ja stabiilne

Lihtne hooldus

Iga toode on valmistatud 14-20 mm kivimassist aluskihist, mis on kaetud 1-1,5 mm paksuse eriti kõva ja läikiva polüesteremailiga (gelcoat).

Kivimassist aluskiht koosneb 80% jahvatatud marmorist, mis on vaakumis segatud sünteetilise vaiguga ning soojuse säilitamise soodustamiseks on sellele lisatud õhuga täidetud mikrosfääre.

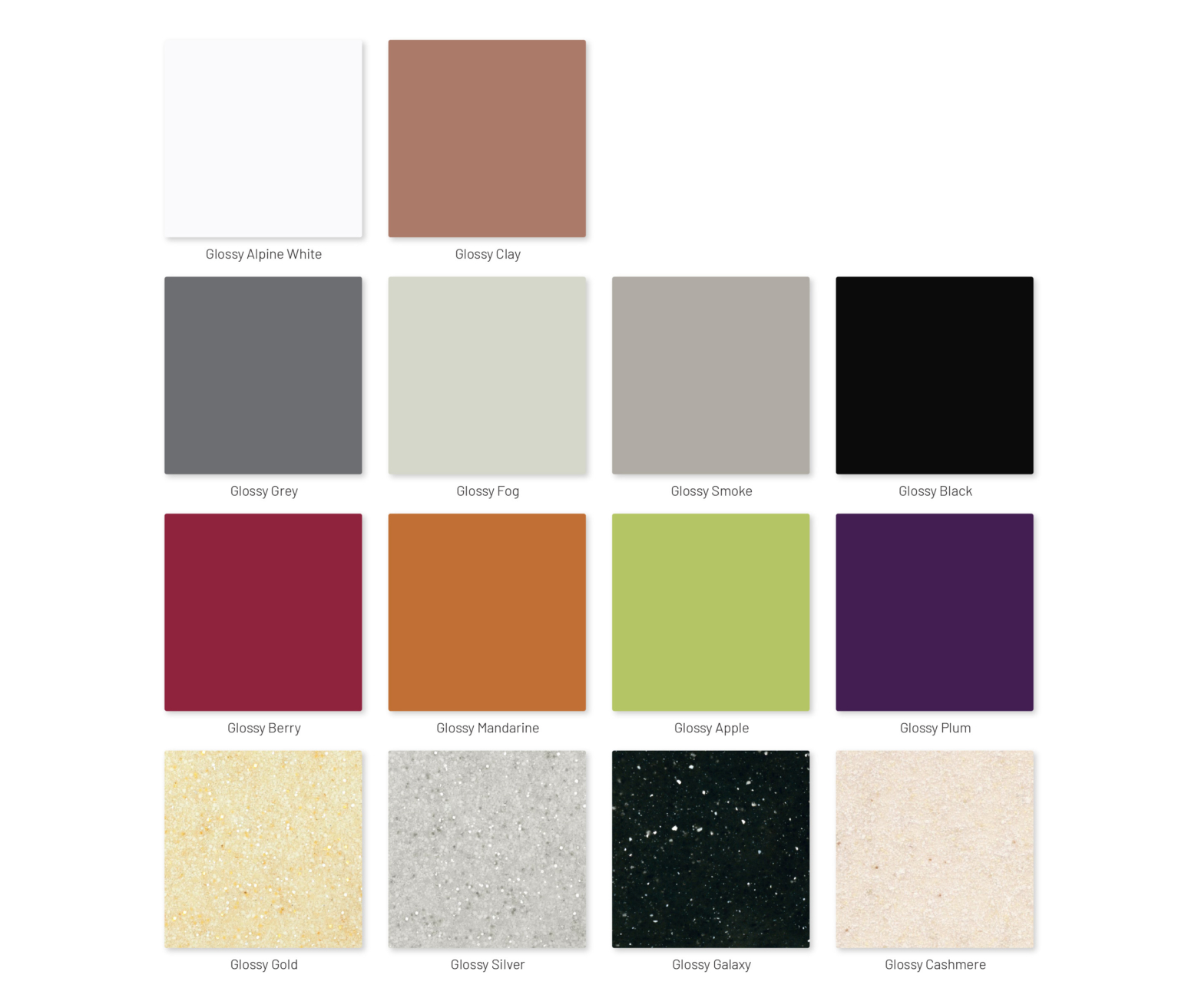

Kivimassist toodete värvi palett